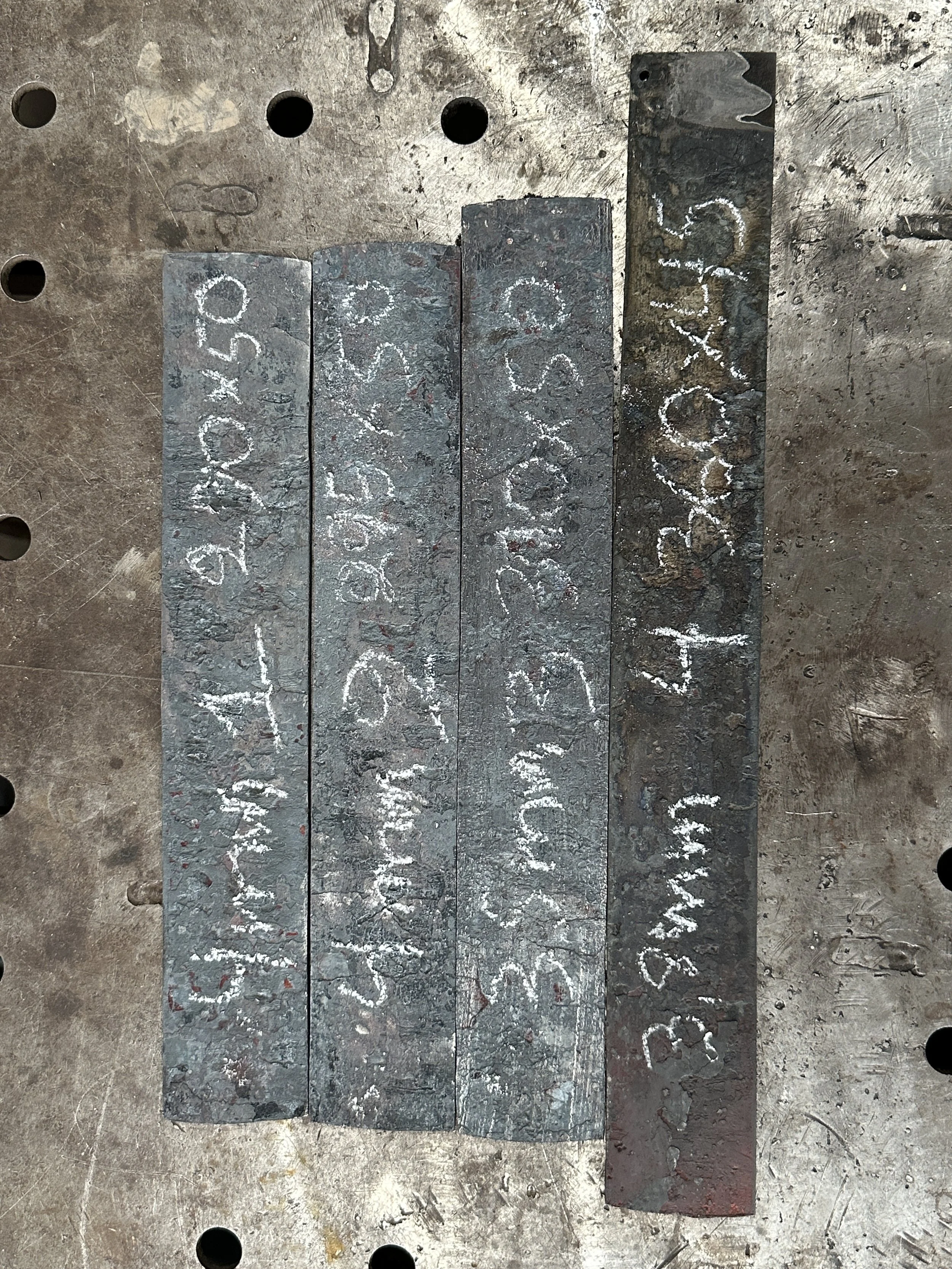

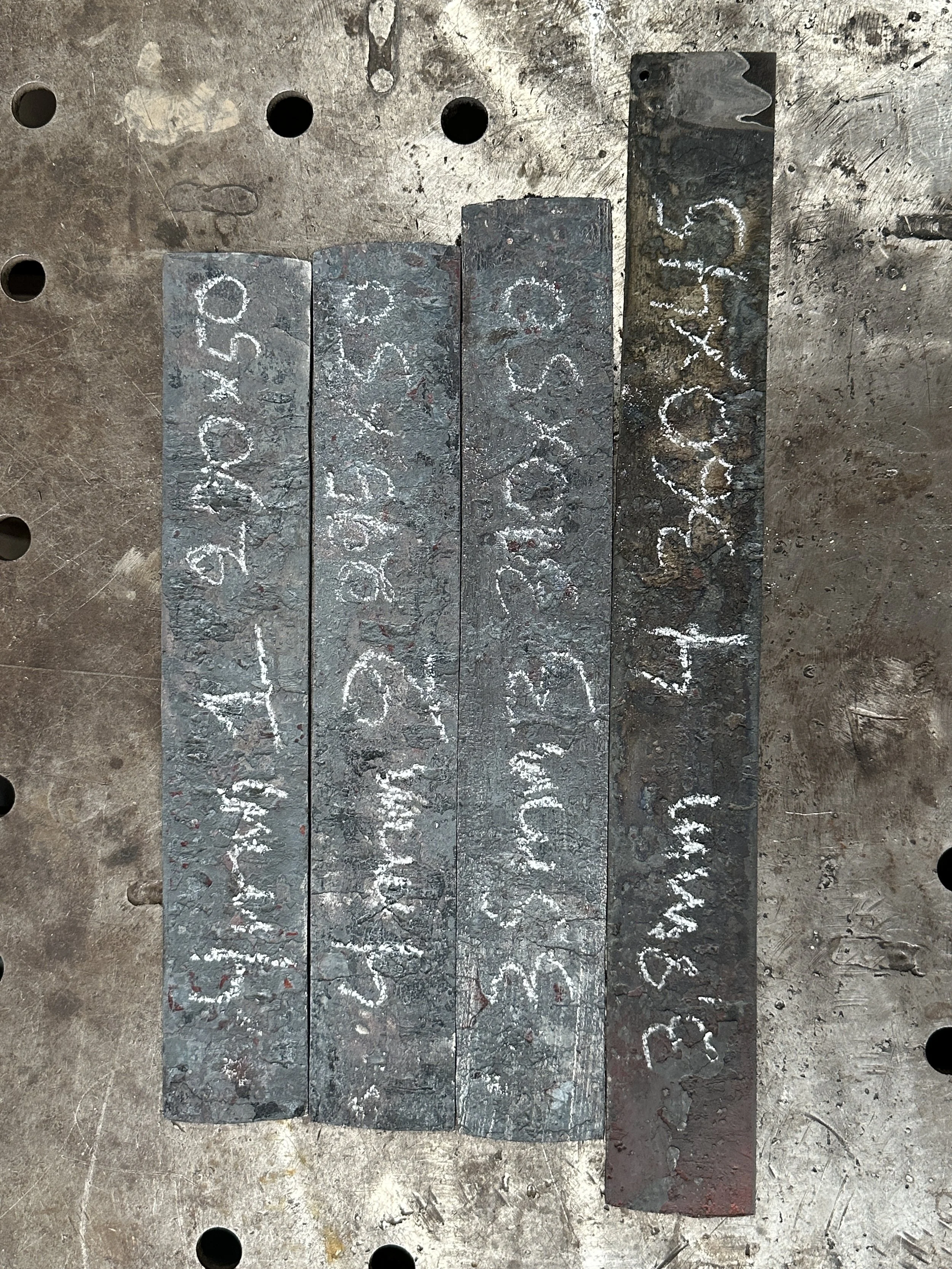

Apex Ultra Go-mai, pure nickel & Wrought Iron Cladding

Apex Ultra Go-mai, pure nickel & Wrought Iron Cladding

The wrought iron of this billets has been harvested from 19th century cart wheels. Having used this wrought iron quite a bit I have found that cart wheel wrought iron was folded multiple times to increase its strength thus when bevels ground and etched the layering pops up very nicely as it has absorbed quite a bit of carbon (see photos). Also the way I make this billets is by forge welding and expanding under the hydraulic press with drawing and flat dyes. In result they come at a ready to use thickness starting from 3.8 to 4 mm with some beautiful layer activity without the need of more hammering. They could definitely be hammered thinner but not get upset . Apex Ultra needs to be forged at slightly higher temperatures 850c+ no more than 950c+, also wrought iron cracks if you hammer it hard at lower temperatures. So basically keep your billet glowing while hammering and don’t get tempted to keep hammering after the glow dissipate. If you follow the above forging directions you can easily expand the hight and the length to achieve large blade sizes.

They also have been hammered flat under the power hammer and descaled but as wrought iron scales quite a bit during forging there are the odd dipper spots which can be ground away if you were after a fully ground blade. (Choose a thicker billet if you intend to grind all the forge finish away )

I am forge welding for a few years now without any major failures but the odd unexpected material failure can happen, in case a fault is proven to be on my side, (ex. you are profiling a blade and you find delaminations prior to any forging or heat treatment) please rest assured that I will replace or refund your billet .

Heat treatment: If you are heat treating from a forge make sure you protect the blade from the direct jet flame of the burner. Muffles can be made out of square tubing or angle iron roof inserts if your burns come down from the top of the forge. Tempare imidiatly after the quench and from room temperature.

Follow the data sheet for heat treatment on apex ultra website

https://www.apexultrasteel.com/downloads